In the sample homogenization process, preserving the sample in its original condition is a seemingly trivial yet potentially complex challenge. Sample preparation in ball mills, for example, is based on the physical mechanisms of friction and impact.

These can cause heat development, which is a critical issue for materials that are temperature-sensitive. RETSCH’s new Mixer Mill MM 500 control is the first laboratory ball mill specially created for the processing of such materials.

Mixer Mill MM 500 control – Introduction Video – RETSCH

Video Credit: RETSCH GmbH

The MM 500 control monitors and controls the temperature of a grinding process. It is a powerful mill for dry, cryogenic and wet grinding processes with a maximum frequency of 30 Hz.

The MM 500 control employs a unique concept for the cooling of samples. The achievable temperature ranges from –100 to 100 °C, providing a novel approach to cryogenic grinding and sample cooling. Sample heating is also possible, as shown in figure 1.

Figure 1. MM 500 control and its operating temperature range, related to the field of ball mills with water cooling, without cooling or cooling with liquid nitrogen. Image Credit: RETSCH GmbH

Cooling Concept

In the MM 500 control, Retsch Screw Lock Jars are used to process the material. These are simply fixed on top of thermal plates for tempering, as shown in figure 2.

Figure 2. Cooling concept based on thermal plates: the sample material is processed in screw lock jars which are mounted on top of the thermal plates. Image Credit: RETSCH GmbH

Heat is successfully transferred from or to the jars because the grinding jars are in metallic contact with the thermal plates. In turn, a thermal fluid tempers the thermal plates.

Technical Innovations and Advanced Design

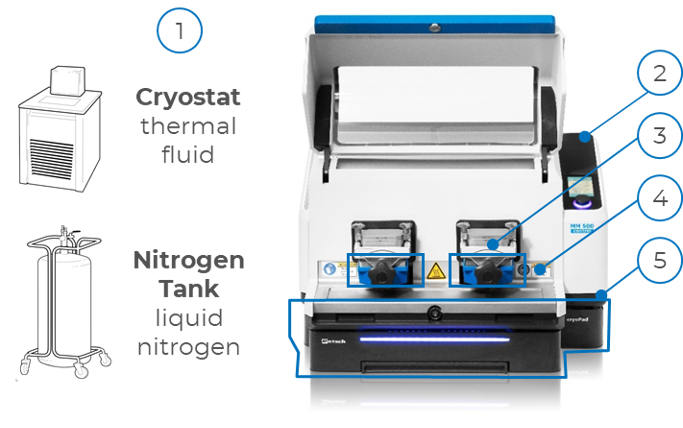

The modern design and the technical innovations of the MM 500 control allow for new features, as demonstrated in figure 3.

Figure 3. Key benefits and unique features of the MM 50 control: 1: Different setup possibilities, 2: temperature monitoring, 3: screw lock jars, 4: thermal plates, 5: cryoPad technology. Numbers are explained in detail in the text. Image Credit: RETSCH GmbH

Different Configurations

The sophisticated internal tubing system enables the use of either liquid nitrogen or another thermal fluid for the tempering of samples. Cooling can be achieved with a liquid nitrogen tank or a regular cryostat.

With the MM 500 control it is possible for the first time to obtain cryogenic temperatures without using liquid nitrogen.

Temperature Monitoring

During the grinding process, the actual temperature of the thermal plates is constantly displayed, offering useful data about the heat development within the jars.

Screw Lock Jars

The screw lock jars allow for easy handling of samples, and also enable high throughput when two jars with a size of up to 125 ml each are used simultaneously.

Grinding equipment of tungsten carbide and zirconium oxide is also an option for cryogenic grinding.

Thermal Plates

Thermal plates allow indirect heating and cooling of samples in a range from –100 to +100 °C.

cryoPad Technology

The mill needs to be equipped with the optionally available cryoPad device extension if liquid nitrogen is utilized for tempering. Thanks to the cryoPad technology, a precise cooling temperature can be chosen and maintained for the first time.

When using liquid nitrogen for cooling, the accessible area ranges from – 100 to 0 °C in steps of 10. The cryoPad’s patented PID (proportional–integral–derivative) system manages the flow of liquid nitrogen inside the tubing system and successfully controls the temperature of the thermal plates.

Objectives of Sample Cooling / Heating

The MM 500 control provides unique advantages for processing sample materials that are sensitive to temperature.

Using this device, time-consuming grinding breaks and challenging sample precooling are not required. Regardless of the particular application, four different objectives can be identified that require sample heating/cooling:

- Preserving Substances for Analysis

When heated to higher temperatures, the chemical or physical structure of materials can change. This means the analyte of interest may not be the same as before the preparation process.

In the case of substances that evaporate at higher temperatures or those that are volatile, the amount of an analyte can be significantly changed by heat development. - Embrittling

Sticky and ductile materials need to be embrittled for homogenization in ball mills. Not all samples require a -196 °C temperature as achieved with liquid nitrogen in standard cryogenic mills. The MM 500 control provides a safe and convenient cooling method with high throughput down to -100 °C temperatures. -

Wet Grinding Below Room Temperature

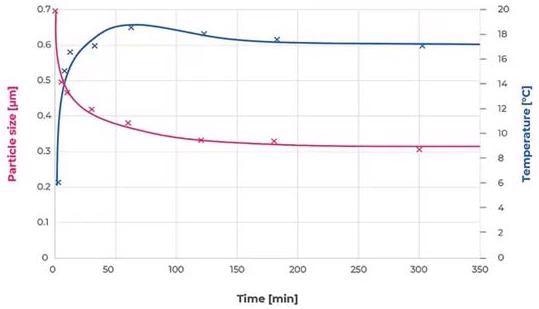

Nano grinding is usually carried out in wet grinding processes at high rotations and frequencies per minute. Temperatures often rise above 80 °C due to the required high energy input.

No cool-down breaks are required throughout the process and after the sample preparation is complete, if the jars are cooled with thermal fluid, as shown in figure 4. The temperature at the thermal plates is monitored during the entire process. Subsampling to verify the fineness during a process is much easier compared to other devices.

Figure 4. Fineness and temperature development in a wet grinding process as a function of time. Jars are cooled with water, which is provided by a chiller set to 4 °C and the temperature stays below room temperature. Image Credit: RETSCH GmbH

- Mechanochemistry

Mechanical alloying and mechanochemical processes need energy to intensify or initiate the formation of material blends or material chemical reactions. Actively heating the jar can significantly enhance the results of chemical reactions.

The MM 500 control’s temperature regulation can also be employed to maintain a specific temperature level during the entire process, which helps to regulate the formation of chemical derivates.

Application Examples

Materials that are affected by heat development can be found in almost every application field, such as biology, agriculture, plastics, chemistry, recycling, engineering, the food industry, pharmaceuticals and even geology. Typical samples are listed in table 1.

Table 1. Examples for temperature-sensitive materials. Source: RETSCH GmbH

| Material | Temperature Sensitive Substance |

|---|---|

| Pharmaceutical | e.g. active pharmaceutical ingredients (API) |

| Good (fresh, greasy) | e.g. food ingredients, flavoring, vitamins |

| Plant material | e.g. pesticides, ethereal oils |

| Polymers | e.g. plasticizers, polyaromatic hydrocarbons (PAH) |

| Cellulose | e.g. color |

| Biological samples | e.g. protein, amino acids |

| Rocks, soil | e.g. organic matter |

Conclusion

The Mixer Mill MM 500 control is a true world first: the first high energy laboratory ball mill that enables the user to control and monitor the temperature throughout a grinding process.

This mill provides new possibilities and perspectives for the homogenization of temperature-sensitive sample materials, wet grinding or cryogenic grinding processes and in the field of mechanochemistry.

To learn more about temperature-regulated ball milling watch this free on-demand webinar.

This information has been sourced, reviewed and adapted from materials provided by RETSCH GmbH.

For more information on this source, please visit RETSCH GmbH.

https://www.azom.com/article.aspx?ArticleID=21300